Metal Hose Assemblies & Stainless Steel Hose Assemblies

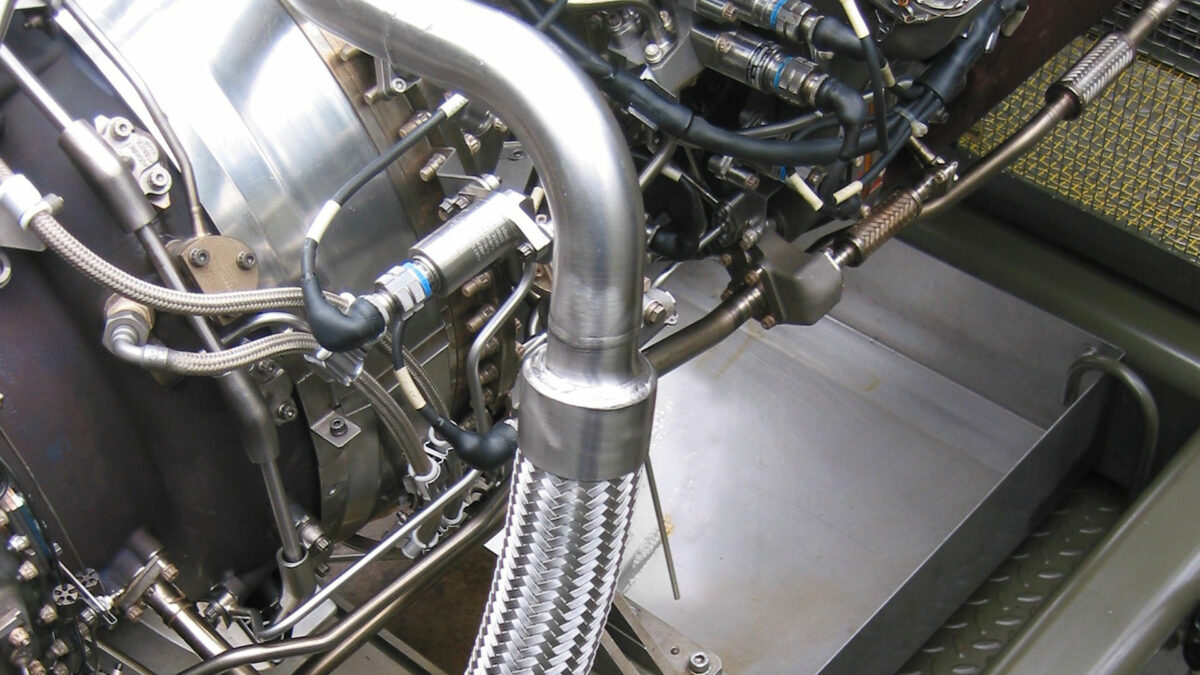

At Flextech, metal hose assemblies and stainless steel hose assemblies are engineered for demanding applications where safety, durability, and performance are critical. These flexible metallic hoses are designed to withstand stringent temperature, pressure, and vacuum requirements across a wide range of industrial environments, providing reliable connections where traditional rubber or thermoplastic hoses may not be suitable.

To explore our wider range of industrial hose assemblies, visit our main hose assemblies page.

What is a metal / stainless steel hose assembly?

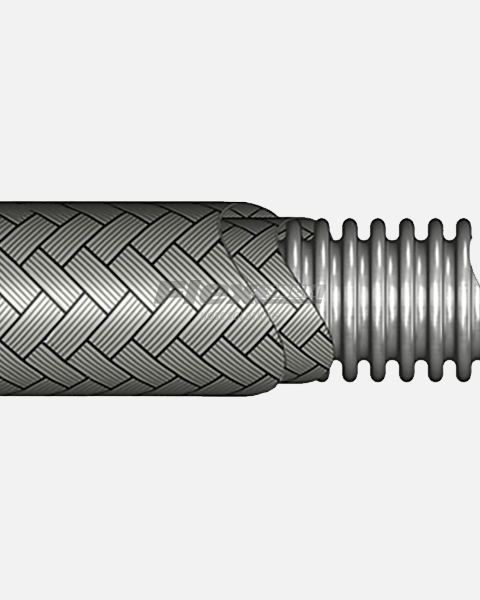

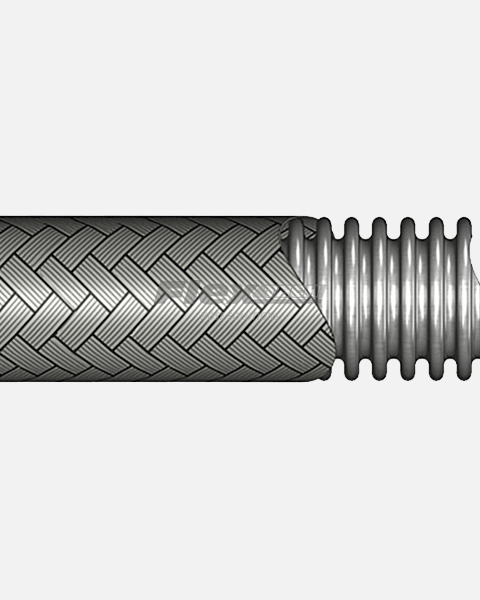

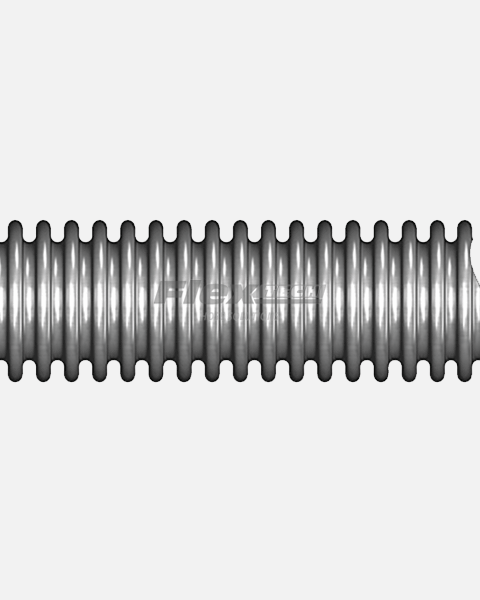

A metal hose assembly brings together a corrugated stainless steel hose, external braid, and correctly specified end fittings or hose couplings to create a flexible connection between pieces of plant and equipment. Stainless steel hose assemblies are typically selected where temperature extremes, vacuum conditions, movement, or vibration rule out conventional rubber or plastic hose.

These assemblies can operate from around -200°C to +600°C, with peak ratings up to 800°C in certain configurations (when correctly specified). They offer excellent chemical resistance, non‑permeable stainless steel construction, and the ability to maintain integrity under full vacuum. When installed within the recommended bend radius, flexible metal hoses help to accommodate misalignment, thermal expansion, and system vibration, improving reliability and reducing stress on adjacent pipework.

Construction and options

Flextech's metal hose assemblies are available as convoluted bore hoses in a choice of stainless steel grades, braids, covers, couplings, and end terminations to match your application. Typical constructions use an AISI 321 or 316 stainless steel liner with a 304 or 316 stainless steel braid, which can be specified as single, double, or triple braided for higher pressure capability and mechanical protection.

Depending on the duty, hoses can be supplied bare, with additional outer covers such as silicone, EPDM, fire sleeve, or flexible insulation, and with weld ends, flanges, threaded fittings, or quick‑release couplings. Assemblies are manufactured to ISO 10380 for corrugated metal hoses and are pressure tested to confirm performance before dispatch. For larger bore sizes above 250 mm or specialist duties, our engineers can advise on suitable metallic hose constructions and associated hardware.

Bespoke assemblies and services

Flextech offers bespoke metallic and stainless steel hose assemblies tailored to individual requirements, including hose diameter, braid configuration, liner material, terminations, and any protective covers. Working with customer drawings or STAMPED selection data, our team can recommend suitable hose, fittings, and accessories for steam, chemical, food, cryogenic, and other demanding services.

Fabrication methods such as coded welding, controlled assembly procedures, and detailed inspection are used to help ensure each hose assembly matches its intended process conditions. In addition to manufacturing new stainless steel hose assemblies, Flextech can support asset management, replacement schedules, and inspection regimes to assist with compliance and lifecycle cost control.

These metal hose assemblies and stainless steel hose assemblies sit within Flextech’s broader hose assemblies offering, which also includes PTFE, rubber, silicone, and thermoplastic solutions available via our industrial hose assemblies homepage.

Applications and key benefits

Metal hose assemblies and stainless steel hose assemblies are used wherever flexibility, resilience, and robust performance are required. Typical applications include:

- Steam, chemical, and petroleum product transfer in manufacturing, construction, and energy installations, where stainless steel hose provides a non‑permeable, fire‑resistant solution.

- High‑temperature hydraulic oils and hot fluids in machinery and vehicles, where a metallic hose is preferred over a rubber hose in extreme environments.

- Corrosive liquids and gases in chemical, pharmaceutical, and medical processes using stainless steel hoses and compatible metallic fittings to maximise service life.

- Food and beverage production lines that require hygienic hose assemblies with stainless steel couplings for cleanability and regulatory compliance.

- Cryogenic and vacuum duties where a flexible metal hose maintains performance at low temperature and under full vacuum without collapse.

- Compressed air and pneumatic connections, where flexible hose assemblies help to reduce vibration transfer and simplify routing in tight spaces.

Key benefits of our flexible metal hose assemblies include broad chemical compatibility, a wide operating temperature range, resistance to permeation and gas diffusion, and the ability to accommodate movement while maintaining a secure seal. A wide choice of hose couplings, valves, and accessories allows stainless steel hose assemblies to be integrated into new or existing pipework systems with minimal modification.

For wider flexible hose assembly solutions, you can start at the Flextech homepage.

Flextech's stainless steel hose range

Our stainless steel hose range covers single and double braided 316 stainless steel standard pitch convoluted metallic hoses in a variety of sizes and pressure ratings. Each hose assembly can be supplied with your preferred end connections and, where required, with additional braiding or protective covers to suit the installation.