What is Bend Radius and Why is it Important for Hoses?

Bend radius is a core concept in hose specification, installation, and maintenance. Understanding and applying the correct bend radius ensures that hose assemblies remain safe, efficient, and durable across industrial, food, pharmaceutical, and chemical applications.

This guide explains the fundamentals of bend radius, why it matters, and how to manage it for optimal performance, with practical advice and internal links woven throughout for further learning.

Understanding Bend Radius in Hose Assemblies

Bend radius refers to the minimum radius a hose can be bent without causing damage or compromising performance. It is measured from the centreline of the hose to the innermost edge of the bend.

Each hose type has a manufacturer-specified minimum bend radius, determined by its construction, materials, and intended use. Exceeding this limit can lead to kinking, internal damage, or reduced flow, which shortens hose lifespan and increases risk.

For a technical overview and detailed specifications, see the hose bend radius guide.

Why Bend Radius is Critical for Hose Safety and Performance

Maintaining the correct bend radius is essential for hose safety, efficiency, and durability. Bending a hose beyond its recommended radius can cause the internal reinforcement to break down, the hose wall to collapse, and flow to be restricted. This may result in leaks, bursts, or contamination, especially in sensitive applications like food, beverage, and pharmaceuticals.

In high-pressure or dynamic environments, correct bend radius prevents accidents and ensures reliable operation.

Learn more about the importance of bend radius in hose asset management.

Measuring and Specifying Bend Radius for Hoses

To get the bend radius right, always start by checking the manufacturer’s datasheet for the specific hose type you're using. Then, measure the routing path carefully and make sure all bends are wider than the minimum specified as tighter bends can shorten hose life or cause failure.

In setups where there’s movement or vibration, use hose guides or supports to keep things properly aligned. And don’t forget to factor in the full system layout, including fittings and any dynamic movement, when planning your hose assemblies. A little extra planning upfront can save a lot of trouble later.

For step-by-step measurement guidance, visit the bend radius resource.

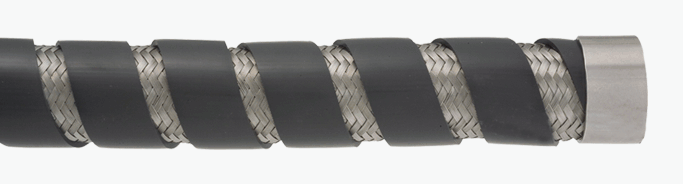

How Hose Construction Affects Bend Radius

The construction of a hose directly influences its flexibility and minimum bend radius. Braided hoses typically allow for tighter bends than rigid, multi-layered hoses. Materials like PTFE, silicone, and rubber each have unique flexibility characteristics. Reinforcement layers, wall thickness, and hose diameter also play a role.

Choosing the right hose construction for your application ensures you can achieve the required routing without risking damage.

Explore flexible hose assemblies for a variety of options designed for demanding environments.

Consequences of Exceeding Minimum Bend Radius

Exceeding the minimum bend radius can cause kinking, which restricts flow and increases pressure drop. It may also lead to cracking or splitting of the hose wall, damage to internal reinforcements, and a reduction in pressure capacity.

These issues can result in unplanned downtime, product loss, and safety incidents. The best thing to do is always adhere to manufacturer recommendations to avoid a failure.

For more on hose testing and inspection, see hose testing services.

Bend Radius in Dynamic and Static Hose Applications

Dynamic applications, such as hoses connected to moving machinery, require special attention to bend radius because repeated flexing can accelerate wear and lead to premature failure if the bends are too tight.

Even in static applications where hoses are typically bent only once during installation, it’s essential to comply with the minimum radius requirements to prevent long-term damage and maintain hose integrity.

When specifying hoses for dynamic systems, always take into account the full range of movement, as well as environmental factors like temperature, vibration, and exposure to chemicals, to ensure reliable performance and longevity.

For advice on movement-heavy environments, see the hose bend radius guide.

Best Practices for Hose Routing and Bend Radius

Effective hose routing is essential for maintaining safe bend radii and extending hose life.

Key practices include planning hose paths to avoid sharp bends and tight corners, using elbows or adapters where needed, supporting hoses with clamps or guides to prevent sagging, and allowing extra length for thermal expansion and movement.

Proper routing not only protects the hose but also simplifies maintenance and inspection.

For more on designing custom assemblies, visit custom hose assembly design.

Industry Standards and Compliance for Bend Radius

Industry standards such as ISO, EN, and FDA guidelines often specify minimum bend radius requirements for hoses in critical applications.

Compliance with these rules ensures safety, product quality, and protects you legally if the worst should happen.

Always check the relevant standards for your sector and verify that your hoses meet or exceed these requirements.

Learn more about compliance and certifications on our quality assurance page.

Practical Examples: Bend Radius in Food, Pharmaceutical, and Industrial Hoses

Different industries have specific requirements when it comes to hose bend radius, reflecting their unique operational and safety needs. Proper bend radius is crucial not only for hose longevity but also for maintaining hygiene, sterility, and safe handling of challenging materials.

Here’s an example of how they work in multiple market sectors:

Food and beverage hoses require suitable bend radii for hygienic installations, as tight bends can trap residues and lead to contamination.

Pharmaceutical hoses must maintain the correct bend radius for sterility and product integrity, with flexible PTFE and silicone hoses often chosen for their bend capabilities.

Industrial hoses, such as those used for chemical transfer or steam delivery, need robust construction and appropriate bend radii to handle high pressures and temperatures.

Find out more about food grade hoses, pharmaceutical hoses, and chemical hose solutions.

Bend Radius and Hose Maintenance

Regular inspection should include checking that hoses are not bent below their minimum radius. Over time, even properly installed hoses can shift or sag, especially in high-traffic or vibration-prone areas.

Implementing a hose register and routine maintenance schedule helps identify and correct potential issues before they escalate into a problem.

For asset management solutions, see hose asset management.

Selecting the Right Hose for Your Bend Radius Needs

Choosing the right hose means balancing flexibility, pressure rating, chemical compatibility, and bend radius. Consult with hose specialists to ensure your selection meets all operational and safety requirements.

Flextech offers a wide range of hoses designed for diverse applications, each with clear bend radius specifications. Browse flexible hose assemblies to find the right fit for your project.

Troubleshooting Bend Radius Issues in Existing Installations

If you notice kinking, reduced flow, or visible hose damage, check whether the hose is bent too tightly. Problem solving by rerouting the hose, using longer lengths, or adding fittings to increase the bend radius, can often help overcome the challenge. Sometimes, and particularly with persistent issues, the only solution is to upgrade to a more flexible hose to resolve the problem.

For technical support, contact Flextech via the contact page.

Training and Best Practices for Bend Radius

Educating your team about the importance of bend radius helps prevent installation errors and extends hose life. As a responsible employee, ensure staff receive training on how to read datasheets, measure bends accurately, and follow manufacturer recommendations.

When staff understand best practices, they are more likely to spot and report signs of hose stress or damage during daily operations, rather than waiting for an inspection report to highlight potential issues.

For more best practices and downloadable resources, visit industry guides.

How Temperature and Pressure Affect Bend Radius

Temperature and pressure can impact a hose’s flexibility and minimum bend radius. High temperatures may soften hose materials, making them more prone to kinking, while high pressure can increase the risk of internal damage if the hose is bent too tightly.

Always use hoses rated for your system’s maximum temperature and pressure, and allow extra margin for safety purposes.

For technical advice, see the hose bend radius guide.

Keeping Up to Date with Bend Radius Standards

Hose standards and best practices evolve with advances in materials and manufacturing.

Stay informed by reviewing industry guidelines, attending training, and consulting with hose specialists to be at the forefront of industry advice and developments.

We cannot stress enough how crucial it is to regularly review your hose register and update your processes to align with the latest industry recommendations. Staying proactive ensures safety, maximizes hose performance, and helps prevent costly downtime or failures.

Download the latest resources from industry guides.

Frequently Asked Questions about Hose Bend Radius

What happens if I ignore the minimum bend radius?

Ignoring the minimum bend radius can cause kinking, leaks, and early hose failure, resulting in costly repairs, safety risks and potentially regulation breaches.

How do I find the bend radius for a specific hose?

Check the manufacturer’s datasheet or the hose bend radius page for technical specifications.

Does bend radius affect pressure rating?

Yes, bending a hose too tightly can reduce its pressure capacity and increase the risk of failure.

Summary: Why Bend Radius is Essential for Hose Reliability

The bend radius is a core factor in hose selection, installation, and maintenance. Respecting the minimum bend radius ensures safe operation, maximises hose lifespan, and reduces the risk of costly failures. By following manufacturer guidelines and industry standards, you protect your people, products, and processes.

For further reading and technical data, visit the hose bend radius resource.