Food Grade Hose Solutions for the Food & Beverage Industry

Food Grade Hoses - Food Safe Hoses

In food and beverage production, the safety and reliability of every hose in your process line is critical to product quality, hygiene, and compliance. Flextech designs and manufactures food grade hose and food safe hose assemblies that support clean, efficient transfer of liquids, semi-liquids, and dry ingredients across a wide range of processing environments.

From low‑pressure washdown to high‑temperature CIP, our hose for food industry applications is engineered for durability, flexibility, and ease of cleaning, while meeting stringent UK, EU, and international food contact regulations.

Food grade hose options for every application

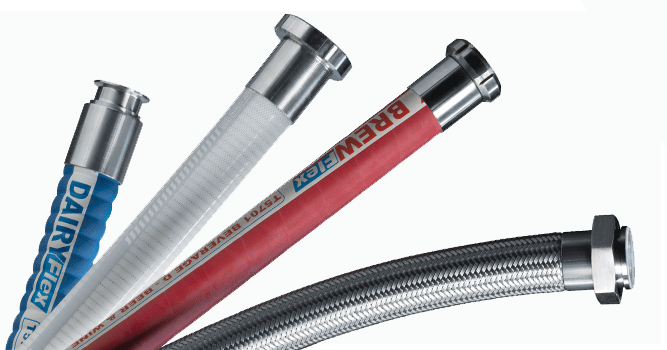

A wide range of food grade hoses is available to suit different products, processes and hygiene requirements, from general food and drink handling through to high-spec pharmaceutical applications. Our range includes metal, PVC, PTFE and silicone hoses for everything from robust, high‑temperature or chemically resistant duties to flexible, lightweight transfer lines, plus specialist options for food and beverage, dairy and brewery use, along with food-safe flexible ducting for air, fumes and light materials handling.

What is a food grade hose?

A food grade hose is a purpose-designed hose manufactured from compounds that are safe for direct contact with products intended for human or animal consumption and tested to recognised food-contact standards. Unlike general‑purpose hoses, a true food hose will not alter taste, colour, or odour, or release harmful substances into the media being transferred.

Typical food grade hose constructions use silicone, rubber (EPDM, nitrile), PTFE, polyurethane, PVC, or stainless steel combined with smooth, non-porous inner liners and correctly specified, hygienically fitted end connections. This design minimises areas where residues can accumulate, supports effective cleaning and sterilisation, and helps reduce microbial growth across the hose’s service life.

Key applications for product transfer in food processing

Food safe hoses are used wherever hygiene, traceability, and product integrity are essential. Common uses include:

- Food and beverage processing lines transferring milk, cream, yoghurt, beer, wine, spirits, soft drinks, syrups, sauces, oils, and other liquid or viscous products.

- Artisanal and industrial food production handling jams, confectionery masses, marinades, chocolate, pastes, and semi‑solid ingredients during cooking, blending, and filling.

- Pharmaceutical and cosmetics manufacturing where food grade water hose, Pharmaflex silicone hose, or PTFE hose is required for high‑purity ingredients, gels, and creams.

- Agriculture and dairy farms, including milking parlours and irrigation systems for edible crops, where hose materials must not compromise product safety.

Food grade water hose and flexible hose food grade variants are also deployed for cleaning, washdown, and CIP supply, where using non‑tainting, compliant hose reduces cross‑contamination risks in sensitive production areas.

Benefits of specifying food safe hoses

Selecting correctly rated food safe hoses brings operational and compliance advantages throughout your process:

- Product safety and quality: Hose materials are odourless, tasteless, and non‑toxic, preserving the natural flavour and aroma of food and drink while supporting HACCP, retailer, and regulatory expectations.

- Compliance confidence: Food grade hoses can be supplied to meet relevant standards such as FDA 21 CFR 177.2600 and 177.1550, BfR, CE 1935/2004, EU 10/2011, NSF 51 and 61, 3‑A Sanitary, USP Class VI and EU Pharmacopeia (for specialist Pharmaflex), plus REACH and RoHS requirements where applicable.

- Performance and uptime: Robust construction enables resistance to oils, fats, acids, cleaning chemicals, and abrasion, while temperature‑rated compounds handle everything from chilled transfer to high‑temperature sterilisation, helping to cut unplanned downtime and premature failure.

- Hygiene and cleanability: Smooth bore liners, optimised bend radii, and correctly crimped hygienic couplings reduce product hold‑up and make hoses easier to clean, supporting efficient CIP regimes and faster changeovers between products or batches.

Materials, temperature ranges, and suitability

Choosing the right food grade hose means matching material to media, temperature, pressure, and cleaning regime. Typical options in the Flextech range include:

- Pharmaflex silicone hoses: For high‑purity applications requiring broad temperature capability, typically from around −60°C up to +200°C, ideal for sterilisation, hot fill, and pharmaceutical processing.

- Multiflex and Brewflex EPDM rubber hoses: Versatile hose for food and beverage transfer where resistance to hot media, cleaning chemicals, and, in Brewflex’s case, high‑strength alcohol is important.

- Dairyflex nitrile hoses: Designed for dairy and fatty food products, balancing flexibility with resistance to fats and oils at processing temperatures commonly encountered in dairies and non‑alcoholic beverage plants.

- Steamflex EPDM hoses: Intended for steam and hot water washdown and sterilisation duties, often operating at elevated temperatures to support hygienic cleaning of process areas.

- PTFEflex PTFE hoses: Chemically inert, wide‑temperature‑range hoses suitable for aggressive media, high‑temperature transfer, and applications where minimal extractables are essential.

- Flexvac polyurethane and PVC hoses: Frequently used for dry food materials, powders, or low‑temperature liquids, where abrasion resistance and light weight are priorities.

- Metalflex stainless steel metallic hoses: Used for demanding high‑temperature, high‑pressure, or steam service where a fully metallic, flexible connection is required.

Matching hose to application ensures that the chosen food grade hose or food grade water hose works safely within its design parameters, resists degradation, and integrates seamlessly with your CIP and SIP processes.

Food grade hose sizes and assemblies

Within food and beverage hoses, the most common internal diameters range from ¼" (6 mm) through to 4" (102 mm), covering everything from small dosing lines to high‑throughput transfer on tanker offload, bottling, and bulk storage routes. Flextech can manufacture bespoke food grade hose assemblies in custom lengths from short, flexible connections of around 250 mm through to long hose runs up to approximately 40 metres, with end connections configured to your plant standard.

Assemblies can be supplied with hygienic RJT, DIN, SMS, Tri‑Clamp, dairy fittings, camlocks, BSP, and other couplings, with options for colour coding, labelling, and hose management tagging to support asset control and auditability across your site.

Food quality hoses vs food grade hoses

The terms “food quality hose” and “food grade hose” are often used interchangeably, but they are not identical. Food grade hoses are specifically engineered, tested, and certified for direct contact with consumable products and carry formal approvals for food-contact use under defined conditions.

Food quality hoses may be well‑made and suitable for certain tasks in food environments—such as potable water supply or non‑critical washdown—but may lack the full set of certifications required for direct contact with food, beverage, or pharmaceutical products. In high‑risk or high‑value applications, a certified food grade hose is generally the appropriate choice to support compliance, audit trails, and brand protection.

Typical lifespan and maintenance of food grade hoses

The service life of a premium food grade hose depends on material, operating conditions, and maintenance. As broad guidance, silicone and rubber food hoses often deliver several years of reliable service when used within their ratings and maintained correctly, with PTFE and stainless-steel options capable of significantly longer lifespans in suitable applications.

To maximise performance, a structured maintenance regime should include regular visual inspections for abrasion, kinking, blistering, or cover damage; verification that fittings remain secure and leak‑free; adherence to recommended temperature and pressure limits; and robust cleaning and sanitisation in line with your CIP protocols. Where appropriate, incorporating hose asset management and scheduled health checks can help identify hoses approaching end‑of‑life and support planned replacement before failures occur.

Flexibility and ease of installation

Food grade hose must combine hygienic performance with practical handling characteristics. Many of Flextech’s food and beverage hoses are designed for easy manoeuvrability and routing in tight spaces, with options for lightweight constructions that reduce operator fatigue in manual handling. Correct specification of bend radius, wall thickness, and reinforcement ensures that hoses remain flexible while withstanding process pressures and vacuum conditions without kinking or collapsing, helping to maintain flow and protect equipment.