T6439 | SPIRITFLEX™ ATEX, DSEAR Fluid Transfer Distillery Hose

Enquire now to talk to one of our specialists.

Standards

- 3-A Sanitary Standards

- BS EN ISO 9001:2008

- EN10204

- EN45014

- SAE J1737

- FDA CFR 21 178.3297

- ATEX Directive 2014/34/EU

- DSEAR:2002

Description

An ATEX compliant fluid transfer hose designed specifically for use with high alcohol spirits within the distillery market, to meet DSEAR:2002 regulations.

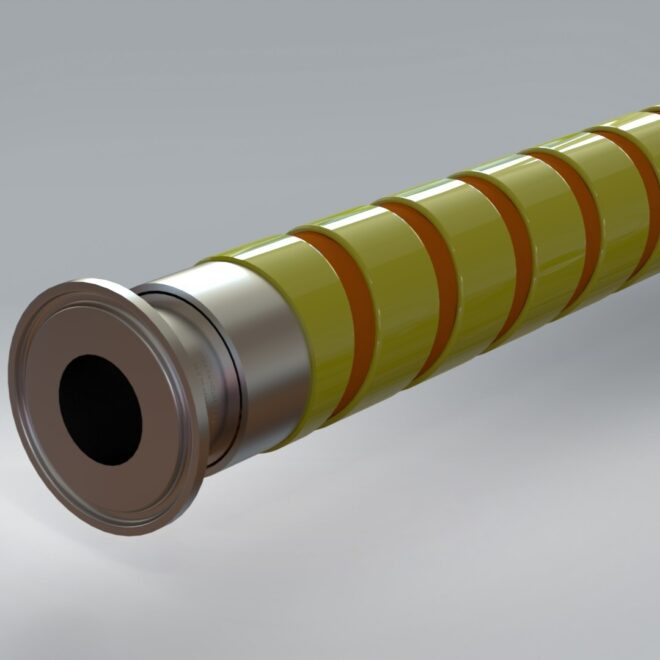

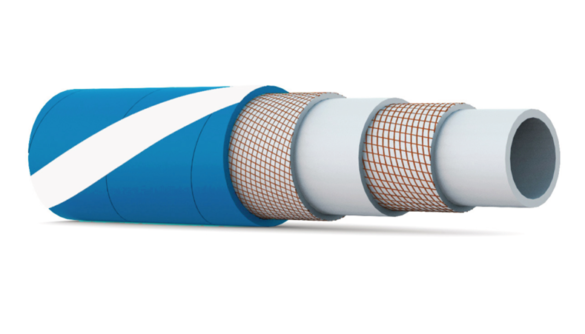

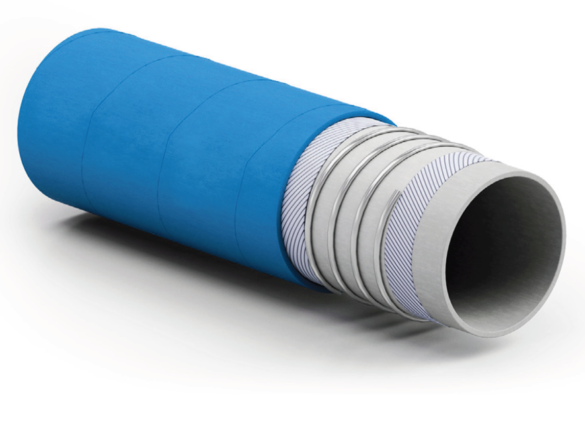

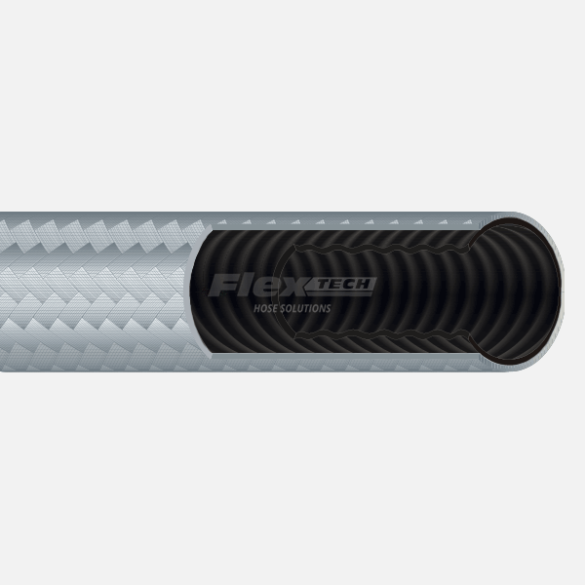

T6439 Spiritflex™ ATEX Compliant hose assemblies are manufactured from an antistatic FDA grade PTFE liner, reinforced with wire spiral, stainless steel braid and orange silicone outer cover with an additional PP yellow spiral guard providing additional protection, increased visibility and helps the hose slide effortlessly over smooth surfaces. This hose is highly flexible, lightweight and has a strong resistance to kinking ensuring ease of use. Assemblies are available with a wide range of hygienically swaged end connections.

Disclaimer

Flextech herby confirms that the PTFE assembly/assemblies on this datasheet will conform to EN 16643-2016, are electrically conductive to ATEX compliance 2014/34/EU and also compliant to PED directive 97/23-EC-category sound engineering practice (SEP). Outside Dimension does not include the external PP (Polypropylene) abrasion guard. External temperature range is limited to +110°c if assembly is fitted with the PP guard. Flextech also certifies that the whole of the supplies detailed hereon have been inspected and tested in accordance with the requirements of your order, and unless otherwise stated above comply in all respects with RoHS legislation and the requirements of subject purchase order.

Working pressures up to: 40 bar

Temp range: -60℃ to 200℃

Key Features

- ATEX Compliant

- Antistatic to <10⁶ Ω minimising risk of explosion

- Wide operating temperature range

- Non-toxic, odourless and tasteless

- Chemically inert liner, resistant to 99% alcohol

- Lightweight and easy to handle

- Resistant to weathering and ageing

- Free from ADI

- Resistant to animal fat, vegetable oil and other edible oil

- Hygienic

Applications

Specifically designed and manufactured for spirits transfer applications in the distillery industry, this hose is produced in compliance with the requirements

for ATEX Zones 0, 1 & 2 allowing high alcohol concentrations to be conveyed safely. All assemblies are provided with corresponding Pressure Test and EC certificates and are tested in accordance with ISO8031.

Construction

Liner: Black, antistatic FDA grade PTFE

Liner Options : available in smooth or convoluted bore

Reinforcements: Stainless Steel Wire, Single layer of high tensile AISI 304 stainless steel braid

Cover: Orange Silicone cover

Protection: Yellow PP Spiral Guard for abrasion resistance and high visibility

Connections

Flextech offer 316L stainless steel, permanently swaged Shawlok® couplings which includes Triclamp, DIN 11851, RJT, SMS, IDF, BSP and BSPT fully hygienic end connections for our Spiritflex™ hose assemblies.