Hydraulic Hose Assemblies

Hydraulic Hose Assemblies Built to Spec

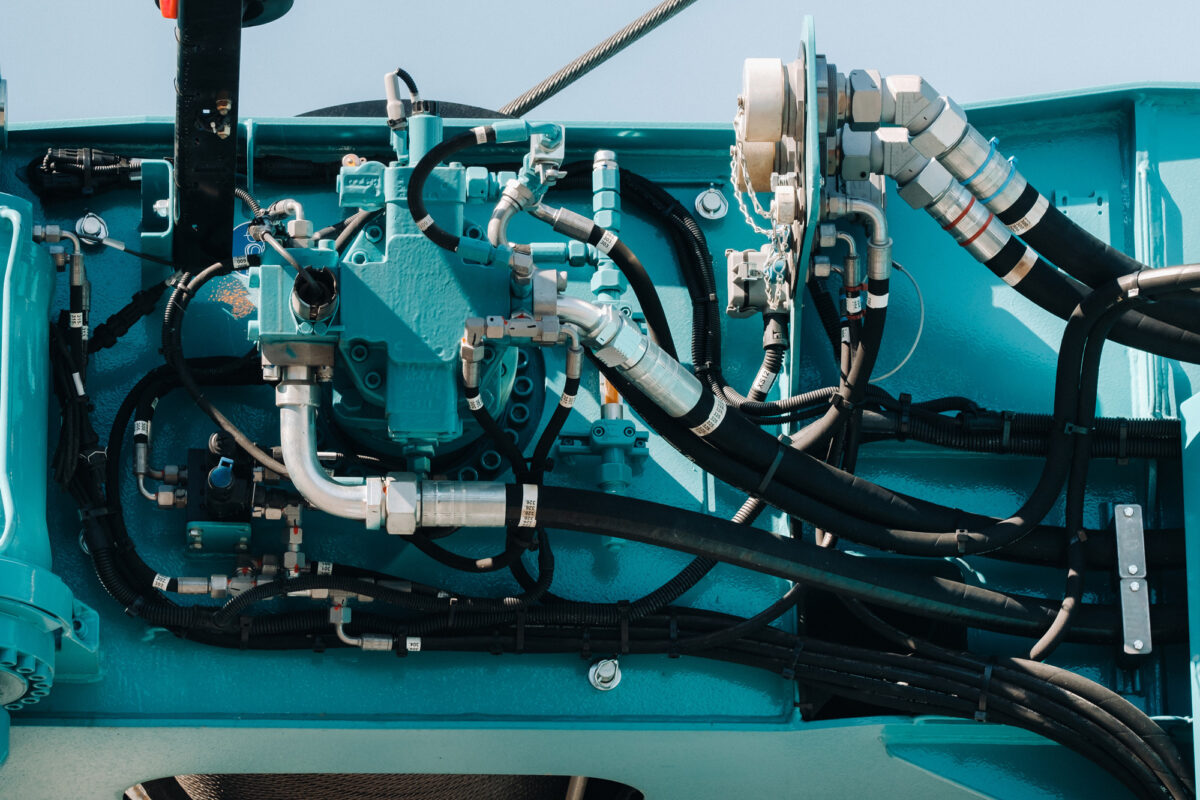

Hydraulic hose assembly kits serve as a backbone of fluid transfer solutions, enabling the efficient transmission of hydraulic power within a myriad of industries and applications. Flextech design and manufacture hydraulic hose assemblies for Original Equipment Manufacturers (OEMs) seeking precision during production and Maintenance, Repair, and Overhaul (MRO) businesses striving to minimise downtime and to offer a convenient and reliable means of integrating or repairing hydraulic systems.

For an overview of all our hose assemblies, see our main hose assemblies page.

About our hydraulic hoses

Flextech is known for delivering high-performance hydraulic hose assemblies to OEM and MRO businesses across various sectors. With decades of experience, Flextech has developed reliable, durable, and efficient hydraulic hoses that support optimal performance in critical applications, including hose assembly solutions built to spec with appropriate hose bore and fittings for each system.

Our hydraulic hose assembly kits tailored for Original Equipment Manufacturers (OEM) and Maintenance, Repair, and Overhaul (MRO) businesses play a crucial role in helping to ensure smooth and efficient fluid transfer within various industries. Flextech specialises in manufacturing these bespoke kits, enabling OEMs and MRO businesses to maintain, repair, and optimise their operations effectively using matched hose assemblies, hydraulic adaptors and accessories for their equipment.

What is a hydraulic hose?

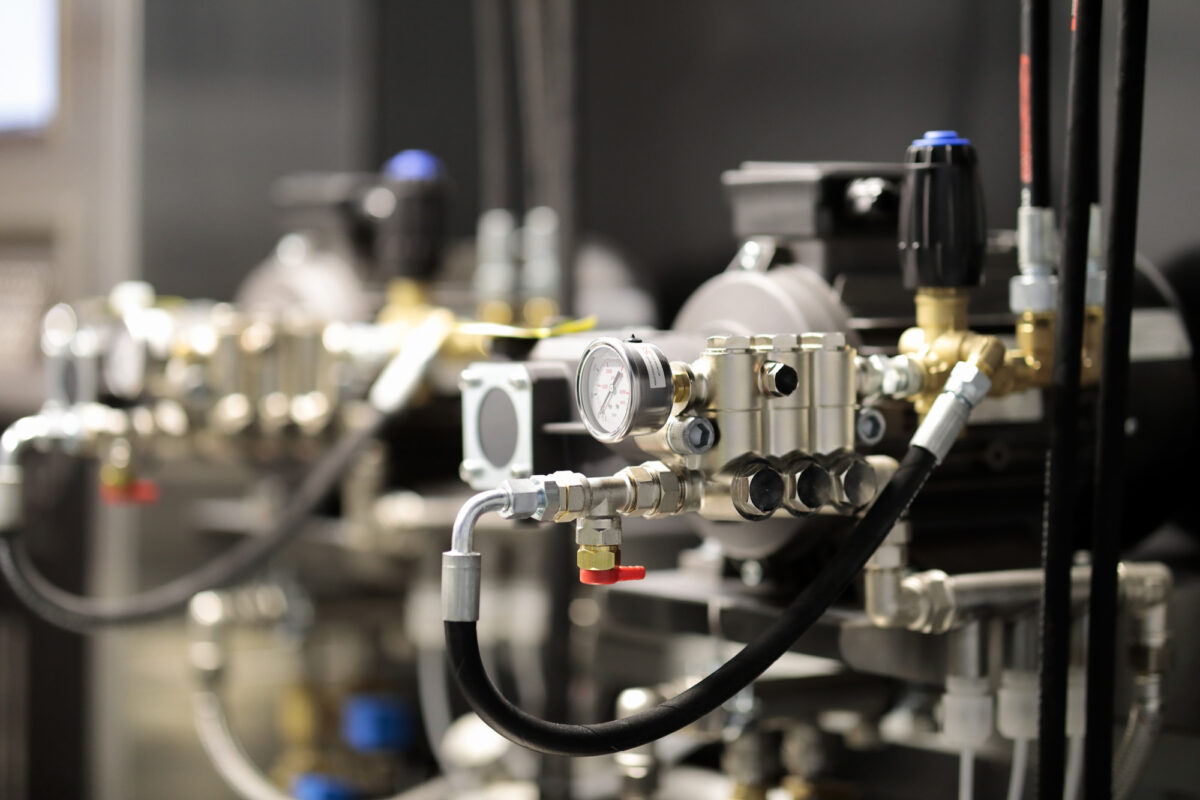

A hydraulic hose is a flexible, reinforced tube designed to transport hydraulic fluid to transmit power within hydraulic machinery. These hoses are the lifelines of various hydraulic systems, playing a pivotal role in helping to ensure smooth and efficient operation between components such as pumps and cylinders. Constructed from synthetic rubber or thermoplastic materials, Flextech’s hydraulic hoses offer resistance to abrasion, temperature extremes, and pressure fluctuations, with steel wire or textile reinforcement used where higher pressure ratings are required. Each hose’s key characteristics, such as hose bore and pressure rating, are set out in the relevant hose datasheet.

Advantages of Hydraulic Hose Assemblies

Hydraulic hose assemblies offer numerous advantages that make them a preferred choice for fluid power transmission in various industries. Here are some key advantages of using hydraulic hose assemblies:

- High Pressure Resistance: Hydraulic hose assemblies are designed to withstand high-pressure conditions, making them suitable for applications where hydraulic systems operate under significant pressure. Selecting the correct hose bore and reinforcement helps the hose assembly handle system pressure safely.

- Flexibility and Manoeuvrability: Hydraulic hoses are highly flexible, allowing them to be routed around tight bends and confined spaces. They can be installed as hose straight runs or stored on hose reels or a hose reel where longer lengths need to be deployed quickly.

- Wide Temperature Range: Hydraulic hose assemblies are engineered to operate over a wide temperature range and can handle both high and low temperatures, typically from around -40°c depending on product selection. Synthetic rubber constructions are commonly used to provide this combination of flexibility and temperature capability.

- Abrasion and Wear Resistance: Hydraulic hoses are constructed with durable materials and reinforced layers, providing resistance to abrasion and wear. Protective covers and compatible stainless steel fittings can be selected where additional durability or corrosion resistance is required.

- Easy Maintenance and Replacement: Hydraulic hose assemblies are designed to be replaceable so that equipment can be returned to operation quickly, helping to maximise productivity and reduce downtime. Using pre-defined hose assembly kits with appropriate fittings and compression fittings can make change-outs quick and straightforward for maintenance teams.

What can you use Hydraulic hose assemblies for?

Hydraulic hose assemblies find extensive use across a wide range of industries and applications due to their ability to transmit hydraulic power efficiently. Some of the key industries and applications where hydraulic hose assemblies are commonly utilised include:

- Construction Industry

- Agriculture

- Manufacturing

- Transportation: Aircraft, Automotives, Marine

- Mining

- Oil and Gas

- Material Handling

- Aerospace

- Defense and Military

- Marine and Offshore

- Forestry

- Waste Management

- Railways

- Robotics and Automation

Flextech's bespoke Hydraulic Hose Assembly Kits for OEM and MRO Businesses

Hydraulic hose assembly kits tailored for Original Equipment Manufacturers (OEM) and Maintenance, Repair, and Overhaul (MRO) businesses play a crucial role in supporting smooth and efficient fluid transfer within various industries. Flextech, a UK manufacturer and provider of fluid transfer solutions, specialises in manufacturing these customised kits, enabling OEMs and MRO businesses to maintain, repair, and optimise their hydraulic systems effectively.

1. Purpose of Hydraulic Hose Assembly Kits for OEMs:

Reliable Equipment Integration: OEMs require hydraulic hose assembly kits to integrate hydraulic systems into their machinery during the manufacturing process. Flextech's kits are designed so that hydraulic hoses meet the specified requirements of the equipment, helping to minimise installation complexities and potential compatibility issues.

Efficient Production and Assembly: By using pre-assembled hydraulic hose kits, OEMs can streamline their production processes and reduce assembly time. This supports productivity and allows OEMs to meet demanding production schedules.

Consistency and Quality Control: Hydraulic hose assembly kits manufactured by Flextech follow internal quality control procedures designed to help support consistent and reliable performance. This helps OEMs deliver high-quality machinery to their clients.

2. Purpose of Hydraulic Hose Assembly Kits for MRO Businesses:

Quick and Effective Repairs: In the MRO sector, downtime is costly. Flextech's hydraulic hose assembly kits provide MRO businesses with readily available components, enabling them to address hydraulic system issues quickly and minimise equipment downtime.

Bespoke Solutions for Varied Systems: MRO businesses often encounter diverse hydraulic systems from different manufacturers. Flextech's hydraulic hose assembly kits can be custom-designed to fit specific machinery, accommodating variations in hose length, end fittings, and other requirements, which simplifies the repair process.

Reduced Inventory Complexity: Rather than stocking a wide array of individual hydraulic components, MRO businesses can rely on Flextech's hydraulic hose assembly kits to cover a range of applications. This helps to reduce inventory complexity, save storage space, and support more efficient inventory management.