What is the STAMPED Method for Hose Selection?

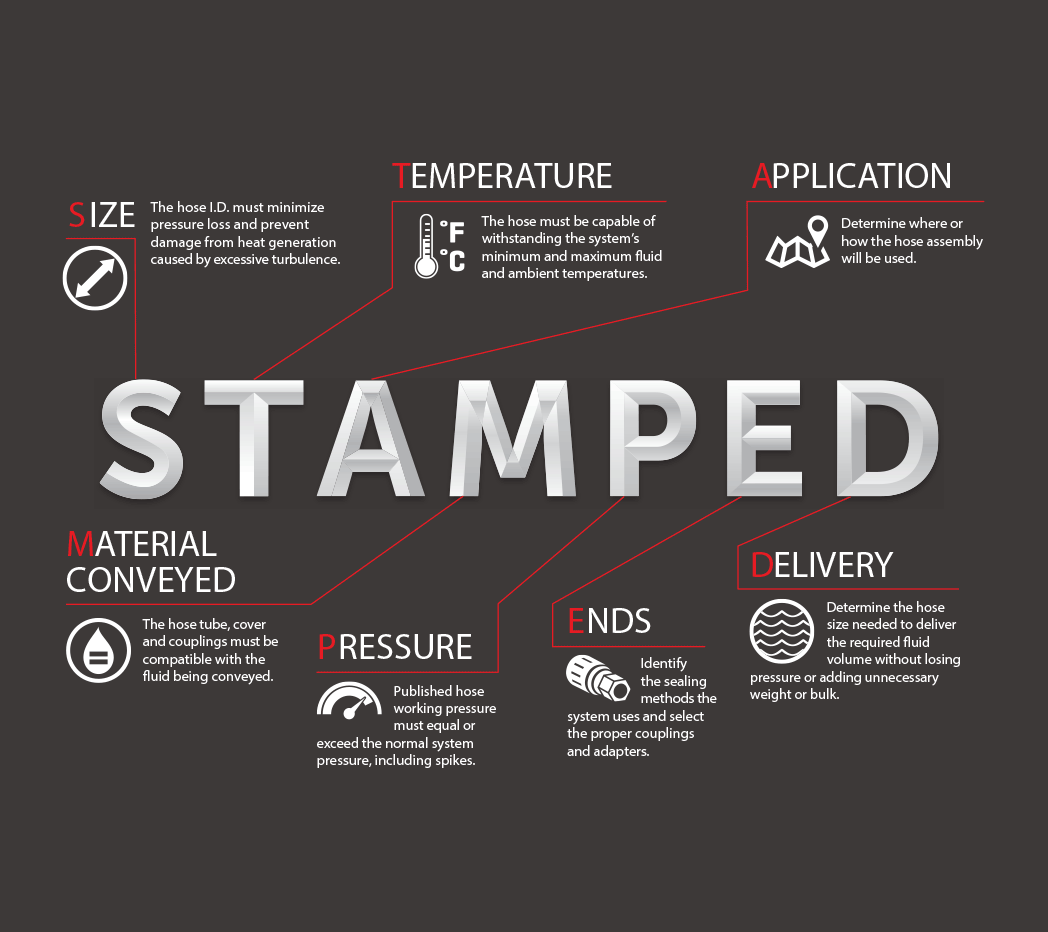

The STAMPED method is the industry standard for specifying and selecting the correct hose assembly for any application. STAMPED stands for Size, Temperature, Application, Material / Media, Pressure, Ends, and Delivery.

By systematically evaluating each of these seven criteria, engineers, buyers, and maintenance teams can ensure hose assemblies are safe, compliant, and optimised for performance and longevity.

For a detailed technical breakdown and support, visit our STAMPED hose selection guide.

Understanding the STAMPED Acronym in Hose Selection

Each element of the STAMPED acronym is essential for identifying the correct hose and assembly, and ensuring compatibility with your system and process requirements.

STAMPED stands for:

Size

Temperature

Application

Material / Media (to be conveyed)

Pressure

Ends (of couplings)

Delivery (flow rate)

Learn more in our STAMPED hose selection guide.

Size: Determining the Correct Hose Dimensions

Selecting the correct hose size is fundamental. The internal diameter (ID) must support the required flow rate without causing excessive pressure loss or turbulence. The overall length should allow for proper routing, avoiding stretching, kinking, or sharp bends.

Also, remember to consider the outside diameter (OD) when space is limited or when selecting compatible end fittings. For replacements, always measure the original assembly’s ID, length, and fitting orientation.

For more on hose sizing, see our STAMPED hose selection guide.

Temperature: Evaluating Hose and Environmental Temperatures

Both the media temperature and ambient temperature affect hose performance and lifespan. Select hoses rated for your system’s minimum and maximum temperatures, and consider whether exposure is continuous or intermittent.

Routing hoses near heat sources or in cold environments may require extra insulation or heat shields. The reason behind this is because using a hose outside its temperature range can cause hardening, softening, or premature failure.

For technical advice on temperature resistance, visit our STAMPED hose selection guide.

Application: Analysing the Hose’s Intended Use

A thorough application review and analysis ensures you select a hose with the right flexibility, durability, and compliance features.When choosing the correct hose type, consider:

The industry (food, pharma, chemical, manufacturing, etc.)

The process (transfer, suction, discharge, cleaning, etc.)

Environmental factors (abrasion, vibration, static, exposure to oils or chemicals)

Regulatory requirements (FDA, EN, ATEX, etc.)

Flextech’s STAMPED hose selection guide provides detailed application checklists.

Material / Media: Ensuring Chemical Compatibility and Safety

The type of material being conveyed, whether it is a liquid, gas, or powder, directly influences the choice of hose tube, cover, and fitting materials. Ensuring chemical compatibility is essential to prevent erosion, swelling, or contamination. For handling aggressive chemicals, carefully verify the compatibility of the hose compound, couplings, and O-rings.

In food and beverage applications, always make sure that all wetted parts are certified food-grade to maintain product safety and hygiene..

Use Flextech’s chemical compatibility guide for reference and to avoid costly mistakes.

Pressure: Matching System and Hose Pressure Ratings

System pressure must never exceed the hose’s published working pressure. Consider both the normal operating pressure and any potential spikes or surges. Exceeding the pressure rating can cause hose rupture or fitting blow-off, leading to downtime and safety risks. Always consult manufacturer data and allow a safety margin.

For more on pressure ratings, see our STAMPED hose selection guide.

Ends: Selecting the Right Hose Couplings and Fittings

End fittings must be compatible with your process connections, pressure requirements, and the media being transferred. Common options include BSP, NPT, JIC, DIN, Tri-Clamp, and camlock fittings, each suited to different industries and applications.

Additionally, custom-designed fittings are available to meet unique specifications or specialised equipment needs, ensuring a secure, leak-free connection that maintains system integrity and safety.

For guidance on end fittings, see our end connections overview.

Delivery: Calculating Flow Rate and System Efficiency

When we talk about ‘delivery,’ we’re referring to the required flow rate and how quickly the product needs to be transferred through the hose. Factors such as the hose’s internal diameter, length, and routing all play a crucial role in flow efficiency and pressure drop.

To select the right hose size, use flow charts or nomographic tools that help determine the appropriate internal diameter based on your target delivery rate and system conditions.

For complex systems, Flextech can help you model flow and optimise hose selection. See more here with our STAMPED hose selection guide.

The STAMPED Method in Practice: Brewery Hose Selection Example

In brewery environments, the STAMPED method is essential for selecting hoses that maintain product quality, hygiene, and safety. For example, Brewflex® hoses are specified using STAMPED to ensure the correct size, temperature resistance (up to 120°C), alcohol compatibility, and hygienic end fittings are chosen. This approach reduces contamination risk and maximises hose lifespan.

For specialist brewery guidance, visit our brewery hose guide.

Common Pitfalls When Skipping STAMPED in Hose Selection

Neglecting any element of the seven stages of STAMPED can lead to:

Batch contamination or product loss

Health and safety incidents

Premature hose failure and increased maintenance costs

Unwanted downtime

Non-compliance with regulations

All of these elements could impact your company financially.Reviewing each STAMPED criterion helps avoid these issues and ensures your hose assembly is fit for purpose.

For more on avoiding selection mistakes, see our STAMPED hose selection guide.

How Flextech Supports STAMPED Hose Selection

Flextech’s technical team works with you to gather all STAMPED data before recommending or manufacturing any hose assembly. Our process includes:

In-depth application analysis

Material and compatibility checks

Custom design and manufacturing

Documentation and certification

Learn more about our approach on the Flextech method page.

Maintenance, Inspection, and Hose Asset Management

Once the correct hose is selected, regular inspection and maintenance are essential for safety and performance. Document all hose assemblies in your asset management system, and schedule routine checks for wear, leaks, or damage.

Flextech’s hose asset management service helps you track hose condition and plan replacements.

Industry Standards and Compliance for STAMPED Hose Assemblies

Hose assemblies specified using STAMPED should comply with relevant standards such as EN 12115, FDA, ISO, and ATEX. These certifications ensure hoses are tested for pressure, flexibility, and chemical compatibility, and provide you with peace of mind. And remember, when purchasing new hose assemblies, always request supporting documentation for your records.

For more on compliance, visit our quality assurance page.

Custom Hose Assemblies and Specialist Solutions

Complex or unique systems may require custom hose assemblies, including bespoke lengths, specialist linings, or unique fittings.

Flextech’s custom hose assemblies service offers design, development, and on-site surveys to ensure you get the perfect fit for your application.

Frequently Asked Questions: STAMPED Hose Selection

Why is the STAMPED method important for hose selection?

STAMPED ensures every critical factor is considered, reducing the risk of failure and ensuring compliance. For a full checklist, see our STAMPED hose selection guide.

Can Flextech help customise hose assemblies to STAMPED criteria?

Yes, Flextech specialises in custom hose assemblies tailored to your STAMPED requirements.

How do I check chemical compatibility for my application?

Use our chemical compatibility guide or consult our technical team for advice.

What documentation is provided for STAMPED hose assemblies?

Flextech supplies full certification, traceability, and technical documentation. Learn more on our quality assurance page.

Where can I find more information on hose selection best practices?

Visit our STAMPED hose selection guide for detailed resources.

Key Takeaways: Why Use the STAMPED Method for Hose Selection?

Although this guide contains a wealth of information, there are three key points you should always keep in mind:

The STAMPED method ensures all critical hose selection factors are considered, reducing risk and maximising system reliability.

Applying STAMPED helps prevent costly failures, contamination, and compliance issues.

Flextech’s technical team guides you through each step, ensuring your hose assembly is tailored to your needs.

Conclusion: Trust Flextech for STAMPED Hose Selection

The STAMPED method is the gold standard for hose selection, ensuring safety, compliance, and long-term performance. Flextech’s STAMPED hose selection guide provides step-by-step advice, technical support, and a full range of compliant hose assemblies for every industry.

For custom solutions, technical support, or to discuss your requirements, trust Flextech as your partner in hose selection excellence.